What are the big GC–MS sample preparation challenges facing food laboratories today?

Among the most demanding areas facing food laboratories today are:

- Authentication

- Trace contamination

- And product quality & aroma profiling

Challenges faced when analysing complex food & drink samples

Chemists working in the food and drink (beverage) industry face an increasing range of challenges and pressures when analysing increasing complex samples. These include:

- Ever-lower detection limits

- Need for comprehensive profiling

- Faster sample turnaround

- Presence of water

- Improving lab sustainability

Markes' Centri sample extraction and concentration platforms help overcome these challenges and deliver the best possible data from your samples.

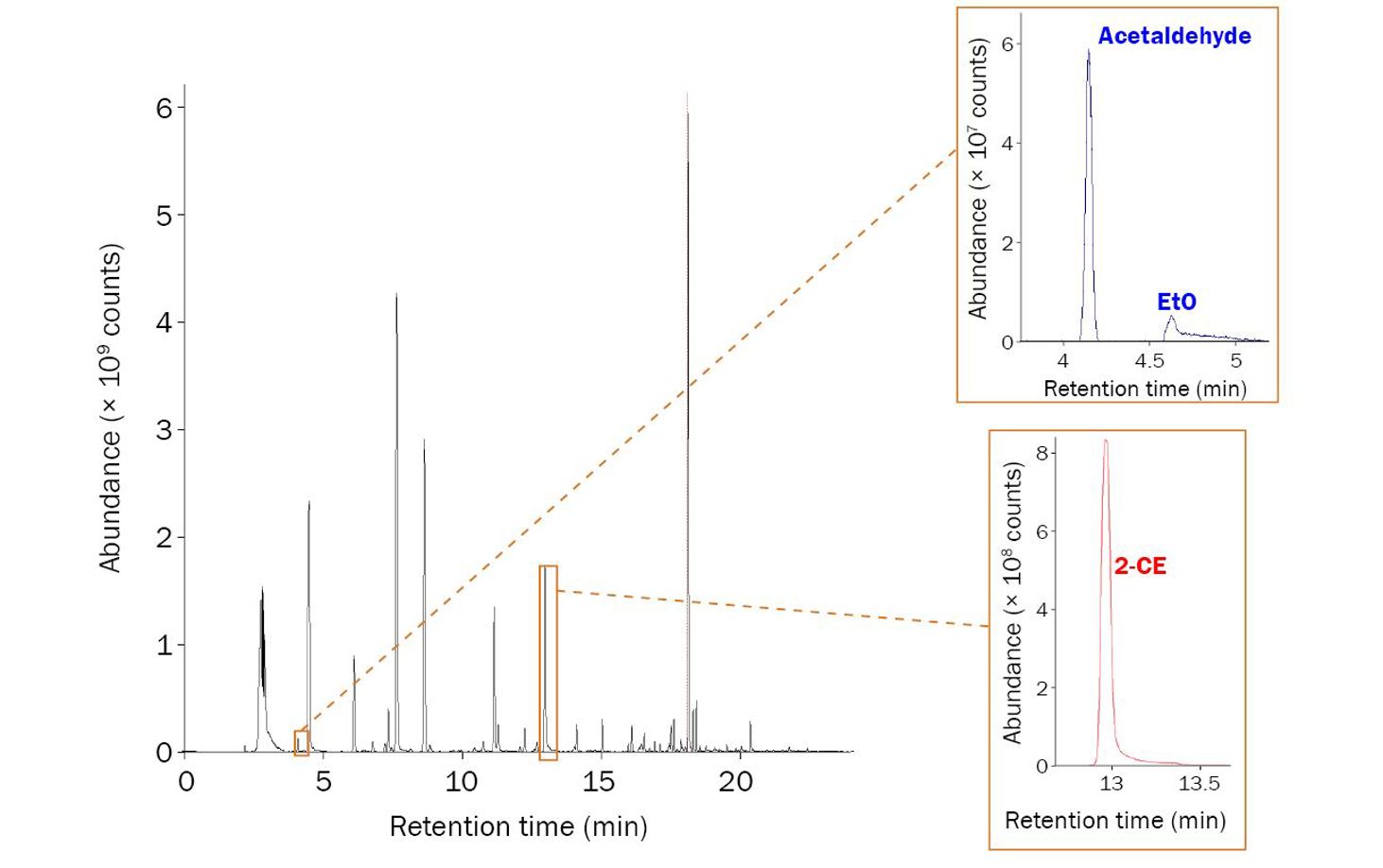

Achieving lower detection limits for trace contaminants in foods and drinks

Routinely monitoring low-level contaminants in foods and drinks requires an analytical approach that is not just high-throughput and adaptable, but also highly sensitive.

To address this challenge and improve sensitivity, our Centri platform provides several possibilities: high-capacity HiSorb™ probes, trap-based focusing for headspace and SPME, or multiple headspace extraction.

Analysis of contaminated sesame seeds, extracted ion chromatograms show target contaminants ethylene oxide (EtO, m/z ion 44) and 2-chloroethanol (2-CE, m/z ion 31)

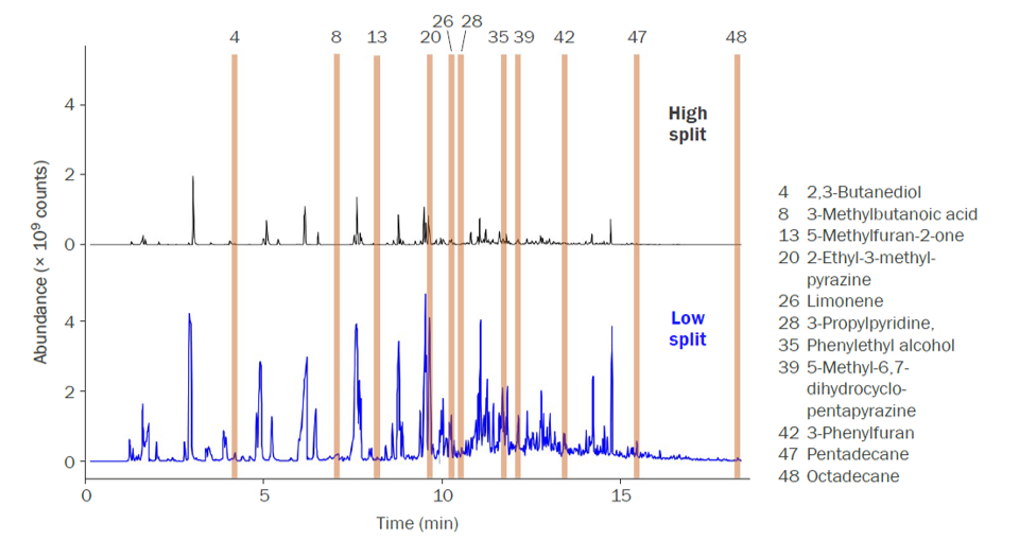

Quickly obtaining overall VOC profiles for foods and beverages

The extreme complexity and variability of many foods and beverages can make it difficult to obtain a comprehensive, representative VOC profile.

But Markes' Centri platform can help you expand the range of abundant and trace-level analytes in various ways, thanks to its range of sample introduction techniques, inert flowpath, and compatibility with HiSorb probes, multi-sorbent trapping and ‘High/Low’ analysis.

Quantifying major and minor components from the same sample of freshly ground coffee using HiSorb (original analysis at high-split) followed by thermal desorption of the re-collection tube (re-collected sample analysis at low-split)

Routinely checking product quality and authenticity

When carrying out checks for food and drink quality or authenticity, comprehensive but quick answers are vital – and that’s where Centri can help.

With its small footprint, Centri will fit into any QC lab, while its 300-vial capacity, automated sample prep capability, and sample overlap mode boost your throughput. Plus you can use Multi-Gas capability to speed up GC separations.

Dealing with water and other high-abundance volatiles

How can you remove water, ethanol, acetic acid, or other volatile components of foods and drinks, so they don’t compromise the analysis?

Centri has answers for you, thanks to its compatibility with hydrophobic sorbents, and the availability of dry-purging and sample splitting procedures. And ‘High/Low’ analysis can bring both major and minor analytes on-scale.

Improving laboratory sustainability

Laboratories are increasingly required to show how they can become more sustainable – but can that be done at the same time as maintaining performance?

With Centri, we think it can, with sorbent-based analyses eliminating harmful solvents, Multi-Gas capability avoiding the use of resource-intensive helium, and Centri’s sampling versatility meaning that you don’t need to keep multiple rarely-used instruments operational.

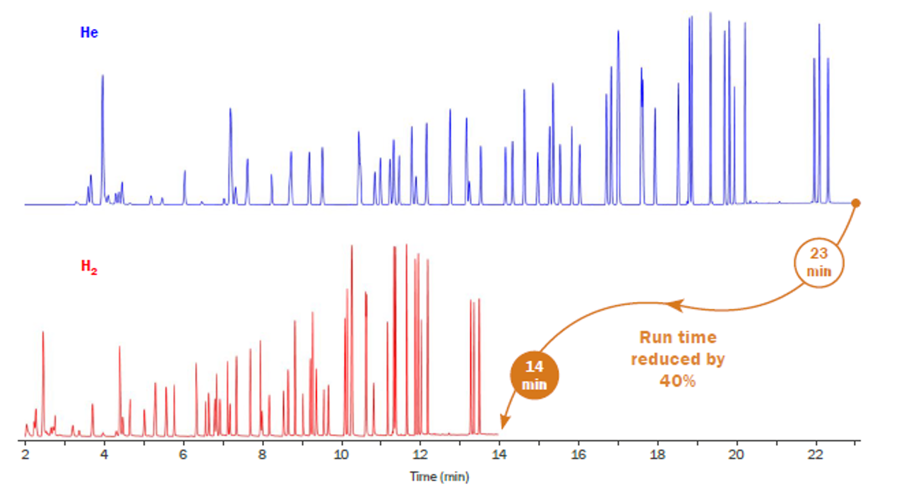

Faster analysis with maximum return on investment while becoming more sustainable with the use of hydrogen as carrier gas

Markes' Centri is the solution to these analytical challenges in the food and beverage field

Markes’ range of Centri® sample automation and concentration platforms can overcome all the challenges faced by analysts working in the food and beverage field.

Unlike alternative GC sample preparation systems, the powerful combination of cryogen-free, backflush trapping technology, and PAL3 robotic automation on the Centri platforms deliver superior quality data while maintaining high productivity.