The release of VOCs and SVOCs from vehicle trim materials (including plastics, polyurethane, foam, wood, carpets, textiles and adhesives) can cause poor air quality inside the vehicle cabin. The concerns surrounding these emissions range from regulating compounds that adversely affect health to reducing the ‘new car smell’, which some consumers find offensive.

Regulations and standard methods

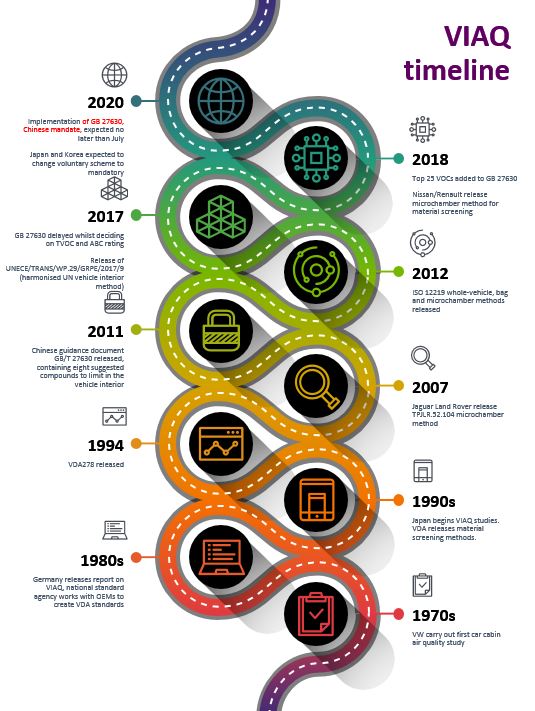

Mandatory regulations in China have accelerated the field of VIAQ and materials testing over the last 10 years, and from 2020 all original equipment manufacturers (OEMs) will need to carry out VIAQ testing in compliance with GB 27630. Korea and Japan are likely to follow suit with mandatory legislation.

Hundreds of methods are used to sample and analyse VOCs and SVOCs released from materials in car cabins, and these are often OEM-specific. As a result, there has been a recent drive by ISO and the UN to harmonise these methods.

Sampling and analysis of VOCs and SVOCs from vehicle interiors

Air samples are pumped from the vehicle cabin onto sorbent tubes, which are then analysed by TD–GC–MS. Exact parameters depend on which regulation and associated methodology is being used.

Regulations

- China: GB/T 27630 – Guideline for air quality assessment of passenger cars. This will be mandatory from July 2020.

- Korea: Automobile Management Act Article 33_3 – Indoor air quality management for newly produced vehicles. This voluntary method will soon become mandatory.

Standard methods used in the automotive industry

VDA 278 – Thermal desorption analysis of organic emissions for the characterisation of non-metallic materials for automobiles. VDA 278 is widely used within the automotive industry for assessing emissions of organic chemicals from small samples of car trim.

![Markes TD Brochure Hero3 Corepurple[2]](/media/zmscvqds/markes-td-brochure-hero3-corepurple-2.jpg?crop=0.55128205128205132,0,0,0&cropmode=percentage&width=350&height=260&rnd=132399686846500000)