Industry standard tubes for thermal desorption…and what matters when selecting them

1 May, 2019

For analytical chemists planning to sample VOCs and SVOCs, selection of ‘industry standard’ sorbent tubes is usually an early item on their checklist.

Working with sorbent tubes and caps with a fixed specification is preferred and sometimes mandatory. Uniformly designed and manufactured tubes support reproducibility and can be used across various thermal desorption systems.

Let’s look at what’s understood by ‘industry standard’ tubes and caps and what’s commercially available.

What are industry standard sorbent tubes & caps?

Criteria for sorbent tubes and caps have been written into international standard methods for thermal desorption for decades. In 1979, Working Group 5 of the UK Health & Safety Executive specified a 3.5 inch × 0.25 inch o.d. (outside diameter) tube-type diffusive monitor, compatible with thermal desorption, that has since become the ‘industry standard’. See The theory and practice of diffusive monitoring.

Other influential standard methods include:

- ISO16000-6: Indoor air - Part 6: Determination of volatile organic compounds in indoor and test chamber air by active sampling on Tenax TA sorbent, thermal desorption and gas chromatography using MS or MS-FID specifies tubes with metal screw caps and PTFE ferrules of length 89 mm (3.5 inch).

- EPA TO-17, Determination of Volatile Organic Compounds in Ambient Air Using Active Sampling onto Sorbent Tubes notes that the most extensively used sorbent tubes are 3½-inch (89 mm) long x ¼-inch (6.35 mm) o.d., stainless steel or glass tubes with a sorbent bed up to 6 cm. It further notes that conditioned or sampled sorbent tubes should always be capped using 0.25 inch brass Swagelok-type screw caps fitted with PTFE ferrules.

- ISO 16017, Indoor, ambient and workplace air - Sampling and analysis of volatile organic compounds by sorbent tube/thermal desorption/capillary gas chromatography -- Part 1: Pumped sampling, Part 2: Diffusive sampling refers to determination of the minimum air flow rate for thermal desorption using standard 4 mm to 5 mm bore, 6.4 mm o.d. sorbent tubes with the sorbent bed set in the range from 12 mm to 18 mm from the sampling end of the tube.

Other influential standard methods include:

- ISO16000-6: Indoor air - Part 6: Determination of volatile organic compounds in indoor and test chamber air by active sampling on Tenax TA sorbent, thermal desorption and gas chromatography using MS or MS-FID specifies tubes with metal screw caps and PTFE ferrules of length 89 mm (3.5 inch).

- EPA TO-17, Determination of Volatile Organic Compounds in Ambient Air Using Active Sampling onto Sorbent Tubes notes that the most extensively used sorbent tubes are 3½-inch (89 mm) long x ¼-inch (6.35 mm) o.d., stainless steel or glass tubes with a sorbent bed up to 6 cm. It further notes that conditioned or sampled sorbent tubes should always be capped using 0.25 inch brass Swagelok-type screw caps fitted with PTFE ferrules.

- ISO 16017, Indoor, ambient and workplace air - Sampling and analysis of volatile organic compounds by sorbent tube/thermal desorption/capillary gas chromatography -- Part 1: Pumped sampling, Part 2: Diffusive sampling refers to determination of the minimum air flow rate for thermal desorption using standard 4 mm to 5 mm bore, 6.4 mm o.d. sorbent tubes with the sorbent bed set in the range from 12 mm to 18 mm from the sampling end of the tube.

Thermal desorption tubes

Industry-standard TD tubes can be used in three ways: packed with a single sorbent bed for diffusive or pumped sampling, packed with multiple sorbent beds for pumped sampling or empty for direct desorption. Markes customers can choose from:

- Universal tubes designed for targeting unknown compounds across a wide range of volatilities

- Single sorbent tubes: Popularly packed with Tenax, Carbograph 1TD and other sorbents

- Multi-bed tubes: Commonly used combinations include Tenax/Carbograph 5TD, Carbopack Y/Carbopack B/Carboxen 1003

- Application-specific tubes: These include tubes packed (and conditioned) in accordance with specific methods like: AirToxics for EPA TO-17, US EPA Method 325 …

- Empty tubes: are recommended only for advanced users with their own sorbent packing expertise and equipment, or when doing direct desorption of liquids and solids

Caps compatible with industry-standard tubes (0.25 inch/6.35 mm inside diameter) are designed for a number of uses:

- Long-term storage caps brass or aluminium Swagelok style caps

- Short-term storage caps also known as push on caps (not for instrument use)

- Diffusion caps for passive sampling

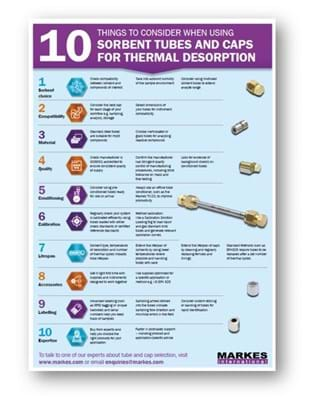

With specifications for sorbent tubes and caps well established, what else should a buyer look for? Download our infographic on some of the top factors to consider when choosing supplies that complement an industry standard approach.