The latest thinking in odour and emissions from plastics – News from Kassel 2019

16 April, 2019

What’s new in the VOC analysis of plastics?

Odour and Emissions of Plastic Materials

For 20 years the conference ‘Odour and Emissions of Plastic Materials’ – often known simply as ‘Kassel’ after the German city where it’s always held – has been the place where analysts from Europe and beyond go to find out the answer to this question.

As the Material Emissions Specialist at Markes, it was a exciting for me to attend Kassel this year for the first time, and discover the latest research trends in investigating VOC emissions from polymers and related materials. Here are a few highlights.

Identifying polymers in microplastics

The keynote lecture at Kassel 2019 was on microplastics – a highly topical area, given the global attention currently focused on the issue of plastic pollution. Dr Ulrike Braun from the Bundesanstalt für Materialforschung und -prüfung (BAM), Berlin, explained how his team have been developing a method to identify microplastic polymers in air and water, which has previously been challenged by time-consuming sample preparation, as well as issues of reproducibility caused by limitations in sample size.

Dr Braun’s method involves the complete thermal decomposition of relatively large plastic samples, and extraction of the resulting products onto a sorptive phase, followed by TD–GC–MS. We were shown how this was being applied to identification of waterborne plastics, and it was especially interesting to see the results of preliminary work on the tiny fragments of plastic in air and dust.

Can you predict odorous emissions from plastics?

Several presentations at 'Odour and Emissions of Plastic Materials’ were focused on the topic of odour profiling of plastics and correlation to sensory data, and in keeping with our own experience over many years, researchers been finding that off-odours are usually caused by trace-level compounds.

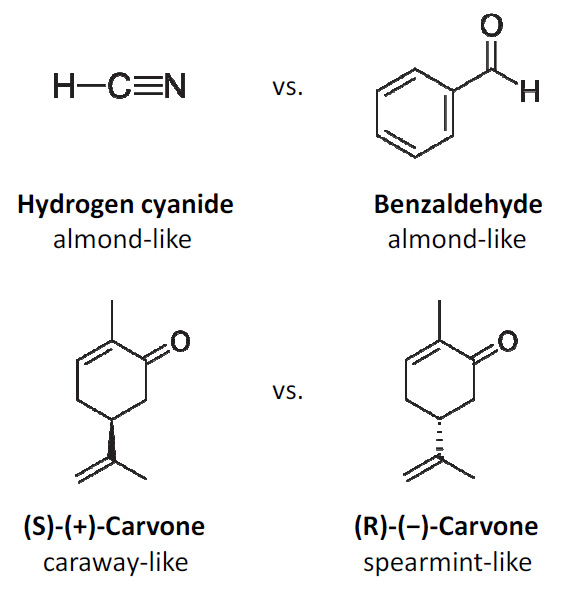

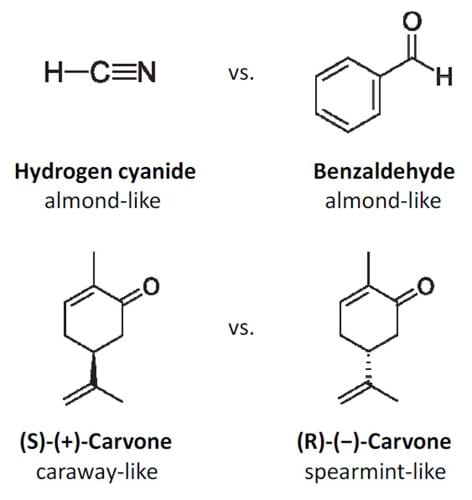

The upshot of this is that the overall odours of polymers can be very difficult to predict – an effect exacerbated by the difficulty in understanding how the human nose responds to individual molecular structures.

Christoph Wiedmer from the Fraunhofer Institute for Process Engineering and Packaging IVV, Freising, provided conclusive evidence of this in his presentation (see examples from his slides opposite), with his comment “there is no way of predicting the odour qualities of unknown  substances based on their molecular structure!".

substances based on their molecular structure!".

Odour compounds in leather – What’s the best sampling method?

Did you know that leather must undergo 47 manufacturing procedures before it’s ready for consumer use? I certainly didn’t until I heard this remarkable statistic in the talk by Thomas Simat of Technische Universität Dresden.

Apart from being introduced to the curious terminology used in this field – including bating, frizing, sammying, fication and curtain-coating – attendees at Kassel learnt about how Dr Simat and colleagues have been comparing the differences in VOC emissions from leather at the various stages of production.

A key aspect of Dr Simat's talk was a comparison of methods used to isolate the odour-active substances from the leather matrix. Solvent-assisted flavour extraction (SAFE) has a reputation as being laborious and strongly dependent on the solvent extraction step, while simultaneous distillation extraction (SDE) has a tendency to show temperature-related artefacts.

The challenge of identifying sulfur odorants in vehicle interior air

For the first time ever, there was representation at Kassel from the China Automotive Technology & Research Centre. CATARC are a long-standing customer of Markes, and Dr Yanmeng Wang from the organisation’s Tianjin facility gave a thought-provoking presentation on the latest in testing of vehicle interior air quality (VIAQ).

Vehicle odour is of course a crucial issue for Chinese consumers, and CATARC are at the forefront of developing a GB/GBT standard to perform VIAQ testing. Dr Wang explained that the current focus of the group is the semi-quantitation of sulfur compounds, which pose the triple challenge of being present in small quantities, being odour-active at low levels, and requiring highly inert analytical systems. He also presented a comparison of sample collection and analysis methods, and the potential of e-nose systems to speed up odour detection.

As highlighted in this presentation, the decision on the best technique to use is clearly not always an easy one, especially when challenging analytes are involved, and we’ve been working with CATARC to help them get the best out of their TD sys tem for this application.

tem for this application.

Equipment for investigating VOC emissions from polymers

As well as being successful for the organisers, ‘Odour and Emissions of Plastic Materials’ at Kassel was also a great event from our point of view, with plenty of contacts made with new and existing customers at our booth, and interest in our poster on VOC emissions from medical devices too.

In particular, a lot of existing users of our Micro-Chamber/Thermal Extractor wanted to know more about our new accessories for preparing spray polyurethane foam samples and calibrating surface-emission measurements. If you’d learn about how these could help you improve the way you sample VOC emissions from materials, just drop me a line.

Kassel is always an interesting conference, and I’m already looking forward to seeing how much this rapidly-changing area will have evolved by this time next year!