Content hub

From application notes to blogs, news items to infographics, we've got a wealth of advice about VOC and SVOC analysis that we'd like to share with you. Simply use the search function or use the drop-down selectors to filter by content type, sampling method and/or application area to discover more.

The POD Sampler and its role in passive air sampling – new data extends applications

Explore

Markes and SepSolve host seminar on analytical strategies to improve data quality in biomarker discovery

The seminar brought together leading experts in volatile biomarker analysis from across the UK, and was hosted by Professor George Hanna and his research team at Imperial College London.

Passive sampling in the workplace: Why thermal desorption is replacing solvent extraction

Discussing why solvent extraction of sorbents remains so widely used for passive monitoring of workplace atmospheres, and showing that TD is not only better from a health & safety perspective, it’s better for lab budgets too.

Why are Markes’ thermal desorption sorbent tubes better than those from other suppliers?

11 April 2023

How long do sorbent tubes for thermal desorption last?

21 March 2023

Panel discussion – Should I move from helium to hydrogen carrier gas?

22 November 2022

How diffusion-locking technology cracked the problem of high-capacity thermal desorption automation

11 November 2022

Markes and SepSolve are realigning under parent company Schauenburg Analytics. What will that mean for our customers?

Alun Cole, Founding Director, discusses.

Helium shortages – how analytical laboratories can prepare for the future

February 2022

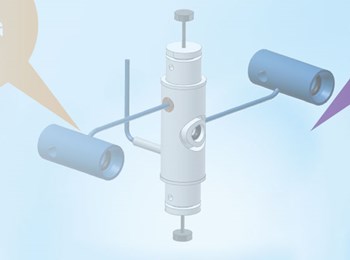

The heart of thermal desorption excellence – valve and trap

28 March 2022

Inaugural Markes International HiSorb user group meeting a success

6 March 2022

Five trends to watch in sample extraction

14 January 2022

Monitoring the air we breathe with passive sampling

16 February 2022

Sample extraction with Centri® – the customer viewpoint

20 September 2021

The POD Sampler – a next-generation passive sampler for VOCs

6 April 2021

US EPA uses TD–GC–MS for vital research into PFAS management

23 February 2021

Passive sampling and its pivotal role in greener sampling of VOCs

16 December 2020

Tenax, Carboxen and other sorbents used for thermal desorption sampling

26 May, 2020