The heart of thermal desorption excellence – valve and trap

28 March 2022

Ever thought about what you need from a thermal desorption (TD) system to give the best analytical results?

As an analytical chemist, I’m looking for a reliable, repeatable and highly sensitive technique that gives me confidence with every analysis.

I’m not prepared to compromise on any part of my analysis, including my TD. I want the peace of mind given by sample re-collection for re-analysis, not the worry that comes with a ‘one-shot’-only analysis. I want to sample a wide range of volatile organic compounds in a single analysis, rather than having to run the TD instrument multiple times to capture all the analytes I’m interested in. I also want a system that operates without the inconvenience and expense of a liquid cryogen. Can you imagine the time and effort saved?

At Markes we call this ‘thermal desorption without compromise’, which I get on my Markes TD systems. How is this done? It’s all down to the proprietary valve and trap at the heart of every Markes TD instrument.

Let me explain…

How the focusing trap improved TD

TD began as an extension of GC in which samples were heated in a flow of inert carrier gas, such that retained organic volatiles and semi-volatiles were desorbed directly into the vapour phase and transferred or injected into the gas chromatograph’s column in the carrier gas stream.

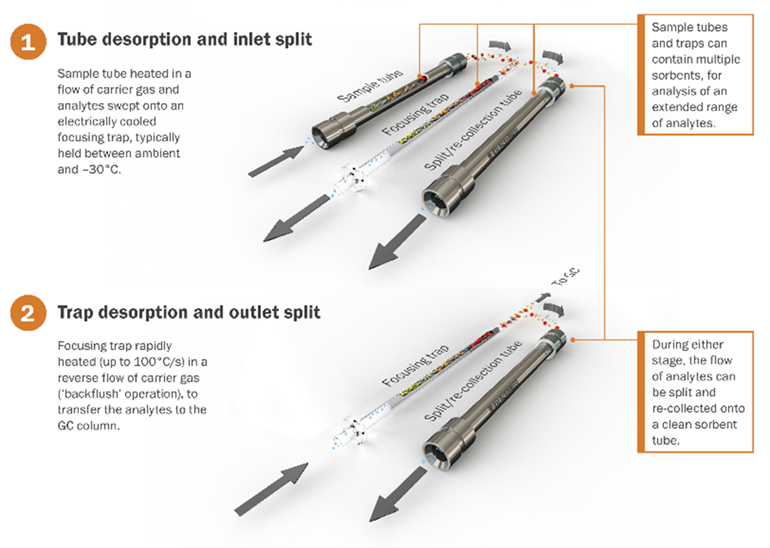

With the introduction of the focusing trap in 1981, the concentration power and potential of TD expanded significantly. The trap enabled two-stage thermal desorption, in which volatile organic compounds (VOCs) are preconcentrated into smaller volumes of gas for injection into the gas chromatograph, optimising sensitivity and detection limits. During the two-stage TD process (Figure 1), up to several hundred litres of vapour are sampled off-line onto a sorbent tube. The sorbent tube is heated, and the analytes are swept onto a focusing trap in 100–200 mL of carrier gas (tube desorption). The focusing trap is heated rapidly and the analytes are transferred to the GC column in 100–200 µL of carrier gas (trap desorption).

Figure 1: Two-stage thermal desorption – sample tube desorption and focusing trap desorption.

The sorbent-packed focusing trap is cooled to –30ºC by an electric Peltier cooler, avoiding the cost and inconvenience of liquid cryogen and the tendency for it to cause ice build-up in the trap box. The combination of sorbent packing and modest focusing temperatures offers quantitative retention of a wide range of compounds and significantly improves the retention of ultra-volatile organics from air or gas samples compared to earlier systems.

Modern traps are typically constructed of inert materials such as quartz, have a reduced internal diameter (typically ~2 mm), can be heated at rates up to 100°C/s and are desorbed efficiently at flows down to 1.5 mL/min to allow splitless or low-flow operation to optimise sensitivity.

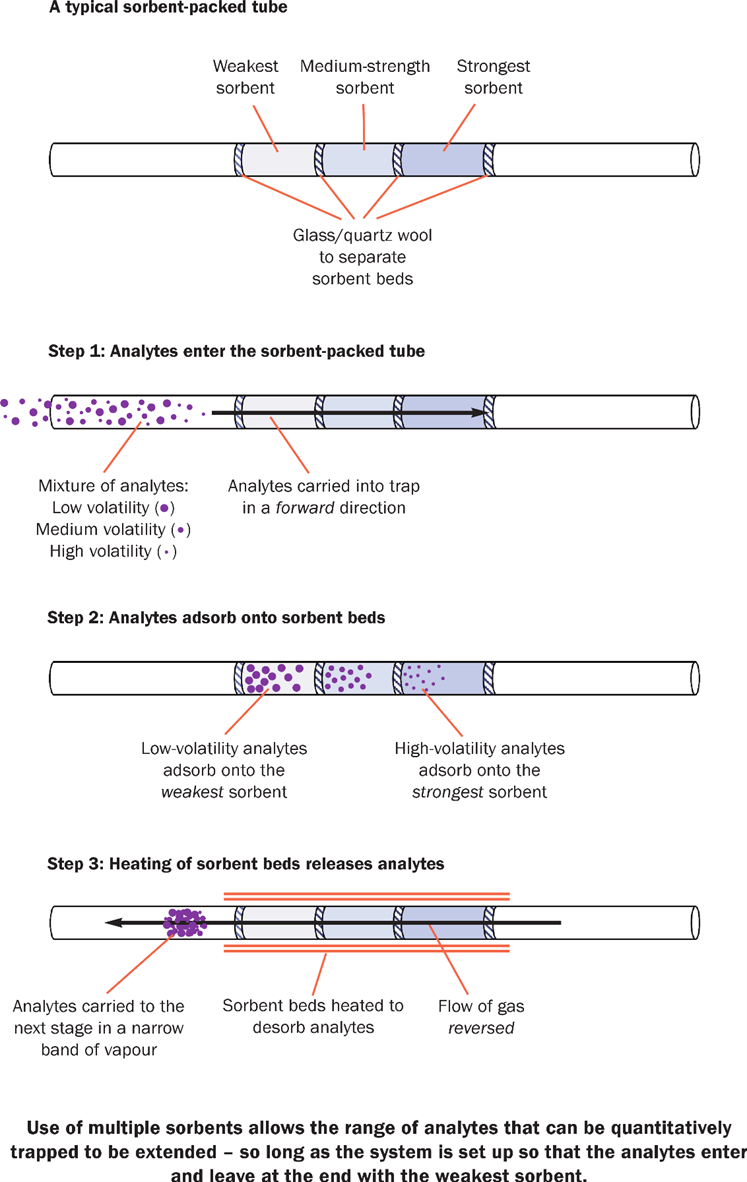

All Markes’ traps are configured in ‘backflush’ mode – analytes enter and leave the trap from the same end to maximise the compatible analyte volatility range (Figure 2). Trap desorption in the reverse direction enables use of multiple sorbent beds, expanding the range of VOCs and semi-volatile organic compounds that can be preconcentrated and analysed from a single sample, and backflushing ensures that heavier analytes don’t get stuck on the strongest sorbents. This enhances the flexibility of modern desorbers (relative to older, forward-flow designs), facilitating both routine (target) and research (non-target) applications on the same system. The traps are also easy to change without having to call an engineer.

Figure 2: How backflushing works

Evolution of the heated valve

An early breakthrough in the use of valves was the addition of a rotary valve in the flow path of the desorber. The valve isolated the sorbent tube from the gas chromatograph, allowing both stringent ‘stop-flow’ leak testing and pre-purging of air to vent prior to desorption of every tube. Valves also enable backflush trap desorption, automated dry-purging of tubes and traps and internal standard addition to the sampling end of the tube. Removing unwanted interferences, such as water and permanent gases, improves signal-to-noise ratios, detection limits and analytical stability, and extends the operating life of capillary columns and the entire GC system.

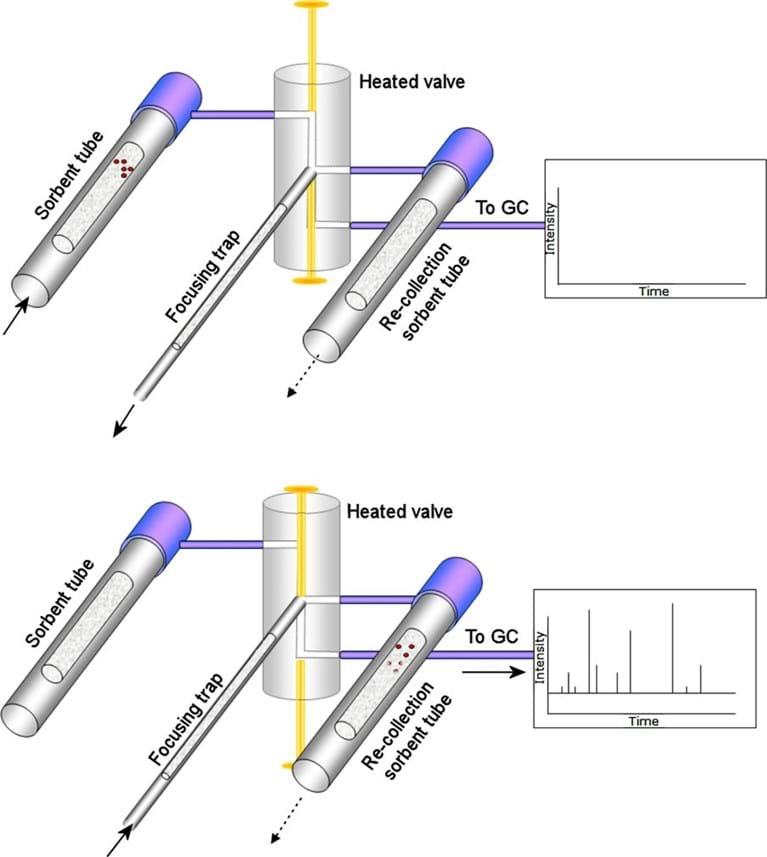

Rotary valves are still widely used in commercial thermal desorbers but can suffer from condensation and carryover of high-boiling analytes due to the challenges of heating the rotary valve uniformly. In 1998, Markes introduced an inert, heated, low-volume, uniformly heated TD-specific valve that enables recovery of both high-boiling semi-volatiles (up to n-C44) and temperature-sensitive species on the same TD platform (Figure 3).

Figure 3: Markes’ inert heated valve.

The valve’s patented design also allows analyte flows from the tube and trap to be automatically split and ‘re-collected’ onto a clean sorbent tube. The re-collected sample can then be analysed again – either to validate the method – as referenced standards ASTM D6196-03, ISO16000-6 – to use a different detection technique, or simply for peace of mind – overcoming the one-shot limitation of many instruments (Figure 4).

Figure 4: Operation of two-stage thermal desorption with integrated capability to re-collect the primary and/or secondary split flow.

How can you find out more?

Download our infographic to discover eight ways in which the valve and trap inside Markes instruments can give you what we've called ‘TD without compromise’.

Download our infographic to discover eight ways in which the valve and trap inside Markes instruments can give you what we've called ‘TD without compromise’.

In addition to the benefits of the trap and valve, Markes’ range of multi-gas-enabled TD instruments have all been independently certified for safe operation with hydrogen carrier gas as well as helium and nitrogen, protecting laboratories against future helium shortages and reducing running costs. Operating with hydrogen increases sample throughput by as much as 50% while maintaining analytical performance. TD–GC–MS methods can be easily converted, and existing columns and consumables can be used, thus allowing fast adoption in busy laboratories.

There is absolutely no need to compromise on sample security and risk your data

‘Sample security in 60 seconds’ – in the video below, we explain how the valve and trap in every Markes thermal desorption system enables sample re-collection – overcoming the ‘one-shot’ drawback of other manufacturers’ TD systems. Meaning that your valuable samples can be secured and quantitively re-analysed.

![Markes TD Brochure Hero3 Corepurple[2]](/media/zmscvqds/markes-td-brochure-hero3-corepurple-2.jpg?crop=0.55128205128205132,0,0,0&cropmode=percentage&width=350&height=260&rnd=132399686846500000)